There appears to be something wrong with multiple Monarch Plus rear shocks. I had one that developed very stiff platform on 20-30% travel and besides the increase in damping force, also made a *klunk* sound. It appeared to be happening only when compression was set to open, trail and climb modes were unaffected.

I first thought that I had bad luck with the damper, but I now know at least 4 instances of this issue in my friends.

Story

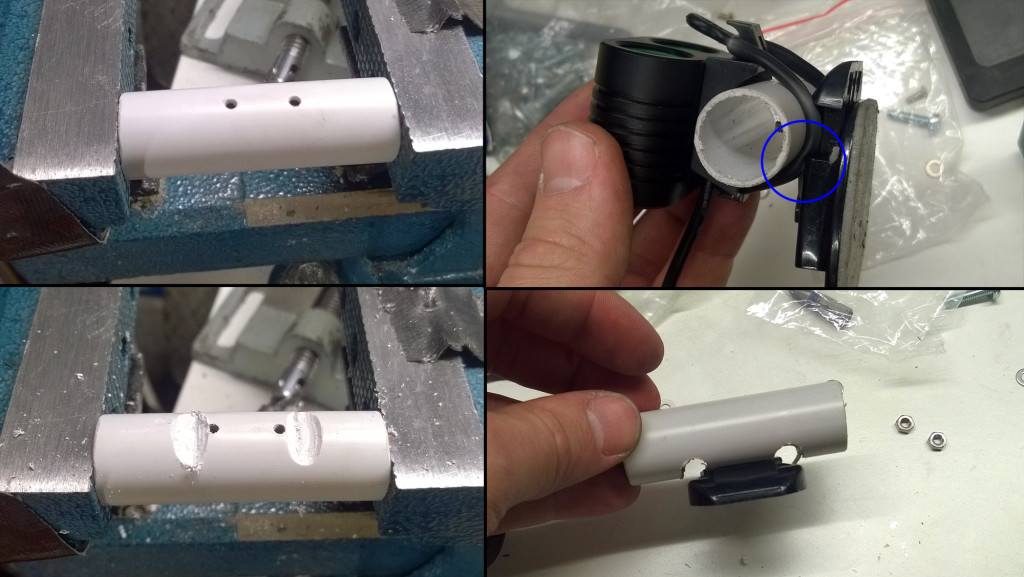

When I investigated the issue and opened the IFP cap to check IFP pressure, some pressure was relieved even when I had not touched the valve core. The valve was few revolutions loose and had been resting on the IFP valve cap (see image below)

The valve was several revolutions loose and I then tightened it. Next I tried to re-pressurize the IFP and when I was removing the adapter+pump, the o-ring from the adapter blew off. Somehow the valve core was still open when the the adapter un-threaded. Finally I ended up cutting the wider part of the valve needle to make sure this is not possible, after this no o-rings have been blown.

Note: if you cut the valve needle, you cannot check the pressure of the IFP, but the valve still works and you can just pump the desired pressure. When filling up, first release some pressure from the ifp (it is best if the shock is not weighted) and then pump it back up to desired pressure.

This way you know that the pressure is what your pump says as when opening the cut valve with pressure instead of pushing with the adapter, you need larger pressure on the pump side than what is inside, to open the valve. This is due the structure of the valve, where it has a larger area on the inside (more force with equal pressure, F=pA).

This made the *klunk* a little softer but did not fix it. I then rebuilt the whole shock and used the same seals/valves at it had been ridden like 2 months. After rebuild (including new oil, grease and bleed of the damper) it has worked flawlessly for months.

Now I check the IFP pressure always when ever I get a new Monarch Plus shock and do it before compressing it even once in the frame. I just got a new frame & shock and when checking, the pressure was released and the valve core was 1½ revolutions loose..

I now hope that it is enough to pressurize the IFP before riding the bike to prevent the *klunk* from happening. My fear is that the IFP could be faulty installed or some other failure..

To check and correct the IFP pressure

- set rebound and compression to open

- open IFP valve cap and hope that no pressure is released (see the video below and sorry about the Finnish, see description for English)

- check if the IFP valve core is loose

- <optional> remove the valve core and cut the valve core needle to make sure it stays closed when needed <optional>

- use valve core tool to tighten the IFP valve (I have come across that they are loose from 1.5 to 4 revolutions!)

- thread Rock Shox Monarch Air Valve Tool (00.4315.027.010 or https://www.sram.com/rockshox/products/air-valve-adapter-tool ) to your shock pump

- pressurize the IFP as Rock Shox service manual instructs (250psi for Monarch Plus)

- thread the IFP valve cap back on

FAQ

Q: I did what you told and everything went to shit.

A: I take no responsibility on what you do based on this guide, you do it on your own responsibility (as every DIY project, duh). This post is mostly about sharing knowledge of a possible issue in your rear shock.

Q: How does the lowered IFP pressure / *klunk* affect my riding?

A: The damping performance is ruined and the platform or “notch” that is created effectively ruins small bumb compliance as the travel stops at the *klunk*

Q: What causes the platform or *klunk*?

A: It is very probable that the lowered IFP pressure induces cavitation in the damper oil, producing gas or foam to hinder the damper smoothness

Q: I already have the *klunk*, what should I do?

A: Contact RockShox, this should be a warranty issue, at least with quite recent shocks.

A2: You can check the IFP pressure as described above, but it will probably not help a lot. Next step is to do rebuild or at least re-bleed the damper. (I will try this the next time I have this issue)

Q: Shouldn’t the IFP be pressurized with Nitrogen?

A: Nitrogen is best but air is good enough and even supported by Rock Shox in the service manual. (air is around 78% Nitrogen and 21% of Oxygen)

Q: The service says that this is normal and related to air pressure equalization between the positive and the negative chamber.

A: Could be, but that is a very small step and shouldn’t happen on every compression. Otherwise the pressure would be constantly leaking from either chamber. The *klunk* described is a very clear platform (you need more force to compress the shock over it) and you’ll definitely know that something is not right