After monitoring my current 2×10 (32-24 : 11-34) gear usage and comparing different oval chainrings I came to a conclusion, that Doval 30T 3032OCP would be good for my usage, but also ordered 32T 104bcd version.

- only oval that is available for 104bcd in 30T size with the 3032 mounting system and 99.5bcd

- “double oval” i.e. rapid transition to minor axis after power stroke on major axis (see mtbr forum for more pictures and details)

- cheap and easily available from ebay

The seller depicts that “no combined shipping available”, so I paid three times the postage as I bought three items (14% oval 30T 3032, 32T 104bcd and a bashring for 3032). When the package arrived, all the items were in same envelope and I did not get the standard 3032 mounting pieces, only the bashring that I bought separately.

The little disappointment with the parts and packaging was soon forgotten as I got the parts that I was planning to install and went down to garage to install them. The 32T OCP5 did not fit with my current bolts (long bolts from shimano 3×10) so I installed the 30T 3032 version and also a new chain plus cassette.

There were no installation instructions what so ever and only instructions that I found from the internet, was a Korean youtube video:

I checked the video for proper order and alignment of the parts and soon got the chainring + bashguard assembled on my crank.

There was no mention of proper torque on the bolts (steel bolts on aluminum threads in the bashring) so I tightened them as tight as it was easy with a basic 3mm hex key. Then installed the cranks back on the bike and tested the switching and chainline.

After everything appeared to be workin I went for a short test drive near the house and it felt great:

I could hardly notice the ovality while pedaling normally but was able to keep the cranks rotating on tight climbs.

So far the oval chainring did exactly what the science said it would, but back at the garage I noticed, that the mounting does not hold and the chainring had slipped. (I also noticed that I was so excited about the ovals that I hadn’t tightened the cranks, so big thank you for Shimano HollowTech II that held the cranks in place =D )

After noticing the slipping, I tried multiple things to increase the friction between the crank, ocp ring and chainring:

- loctite (with over 24h cure time, but it the thread locking compound was not suited for the aluminum surfaces)

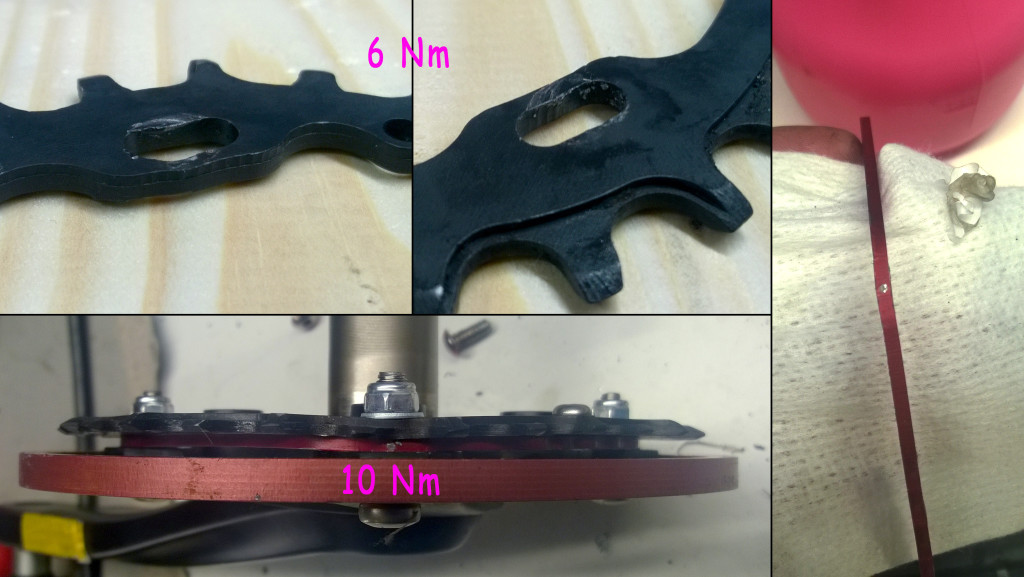

- 6Nm of torque on the bolts

- mounting tape between the surfaces

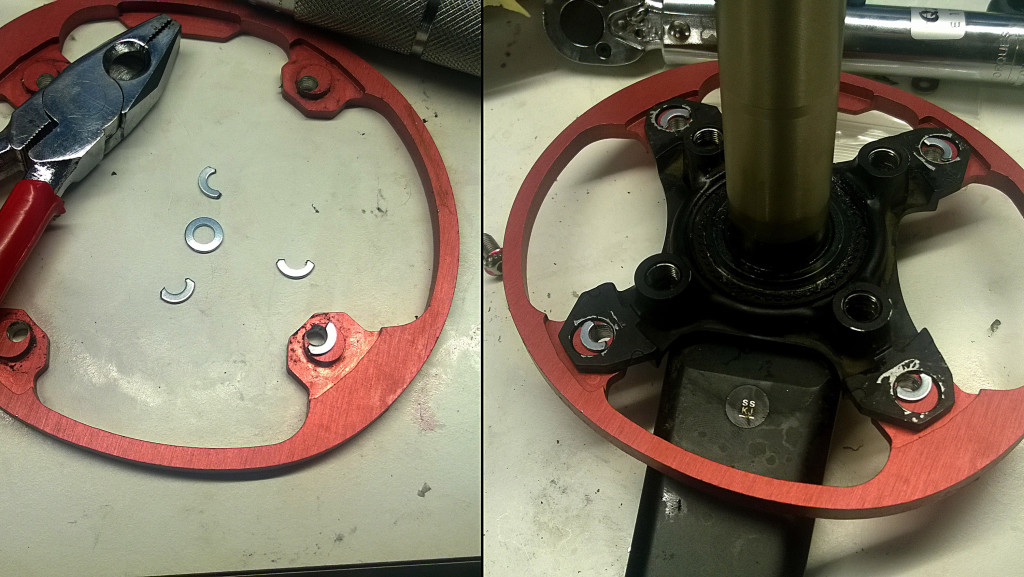

None of the above seemed to hold the chainring in its place. After some investigation, this was no surprise as the area of the mountings surfaces is minimal: the ocp ring (red) is the only contact between the crank and the chainring, and as you can see from the pictures, the ocp ring is really narrow. On the crank side, the bashring even adds to the lack of the surface are, as it does not protrude deep enough to support the ocp ring.

Because this design, it is nearly impossible to get enough friction to hold everything in its place. I couldn’t find any surface locking compound from local shops so I even tried more torque (applied with torque wrench) and got the following results:

- 6 Nm still enabled the slipping and the bolts were able to eat into the AL6061 chainring.

- 7-8 Nm was enough to strip the threads from the aluminum (but I was prepared to this with T25 head M5 bolts and nuts) and the torque was still not enough to keep the chainring from slipping.

- 10 Nm started to bend the chainring and the ocp ring

The bending was possible as the bashring is not deep enough to support the ocp ring. I was determined to get the chainring mounted, so the next fix was to try to add some support with the materials at hand.

I first straightened the chainring in a vise and then I cut some washers to fit around the bolts for added friction area and to support the parts from bending.

After the the cut washers were added, I tightened the bolts to 9 Nm to prevent any more damage on the doval parts ( I also wouldn’t recommend much more on M5 bolts.. ). I added some permanent marker to to monitor the possible slipping.

With the added surface and support from the washers combined with through bolts, the system seems to be holding after a week of riding. Note that previously the slipping occurred instantly when enough pressure was applied on the pedals. So it could be tested on the yard by standing up and pedaling while braking with the front brake.

2 thoughts on “Doval 30T MTB3032 14% oval”